Construction inspections: Best practices to avoid rework and deliver your projects on time

A construction project is not complete without an inspection. And most likely, multiple inspections. They must be conducted regularly throughout a project to make sure the job gets done the right way. Inspections can encompass a variety of duties, from safety to deficiencies to QA/QC work, all of which involve attention to detail and thorough issue tracking.

As a crucial part of construction, inspections can have a direct impact on a project’s efficiency. For this reason, following best practices when conducting inspections is the best way to ensure a project is built to plan, while keeping the process streamlined and efficient.

Why are construction site inspections important?

Construction projects are often complex and involve a great number of tasks and teams. Inspections are essential to ensure the work is being done the right way, according to rules and regulations, on time and within budget. By checking in regularly through jobsite walkthroughs, companies can ensure quality control and productivity of a project, all while making sure safety rules are being followed.

When should jobsite inspections occur?

In construction, you can’t wait until a project is finished to conduct an inspection. Instead, you should regularly check the jobsite and tackle deficiencies as soon as they are discovered. This practice will avoid creating a cascade of defects, and consequently reduce delays and extra costs. Regular inspections also ensure that the jobsite is respecting health and safety regulations, which is important to prevent injuries and costly penalties.

Types of inspections

Daily/progress inspections

Daily inspections, also called progress inspections, are routine walkthroughs of the jobsite to review and document the work done on a given day. The inspector will evaluate if the project is progressing according to schedule and identify quality issues, safety hazards and potential code violations.

At the end of a daily inspection, a report will be created, often called a daily log. This document includes important information like photos and videos of the jobsite, a list of the work completed that day, the weather, material deliveries, people who were present onsite, and much more. An inspection report can be easily created in a construction management app like Fieldwire and shared with stakeholders to keep everyone informed of a project’s status.

Quality control (QC) inspections

The main goal of these types of inspections is to guarantee that the quality of the work matches the project’s and the client’s requirements. By managing quality control, contractors can avoid rework and therefore reduce delays and extra costs.

QC inspections consist of checking if the materials used, the equipment installed, and the execution of the work present any issues. They can be conducted by a quality control manager or a site inspector. Quality control inspectors walk the jobsite to create a punch list with the items that require corrective action. The deficiencies then get distributed to the responsible subcontractor.

Health and safety inspections

Health and safety inspections evaluate if a site complies with safety standards and regulations by identifying hazards and confirming that safety protocols are in place to protect workers and visitors. They are conducted by specialized inspectors, either internally within the construction company or externally by regulatory bodies or third-party inspectors.

Fall protection measures, scaffolding practices, storage and handling of hazardous materials, and the correct use of personal protective equipment (PPE) are some of the aspects examined by the inspectors.

Safety is a priority in any construction project, and conducting regular inspections are crucial to minimize risks, reduce the potential of legal liabilities, and promote a culture of safety among workers. Health and safety inspections are not only an obligation, but also an essential aspect to the efficiency of a construction project.

Best practices for inspections

Use a construction management app

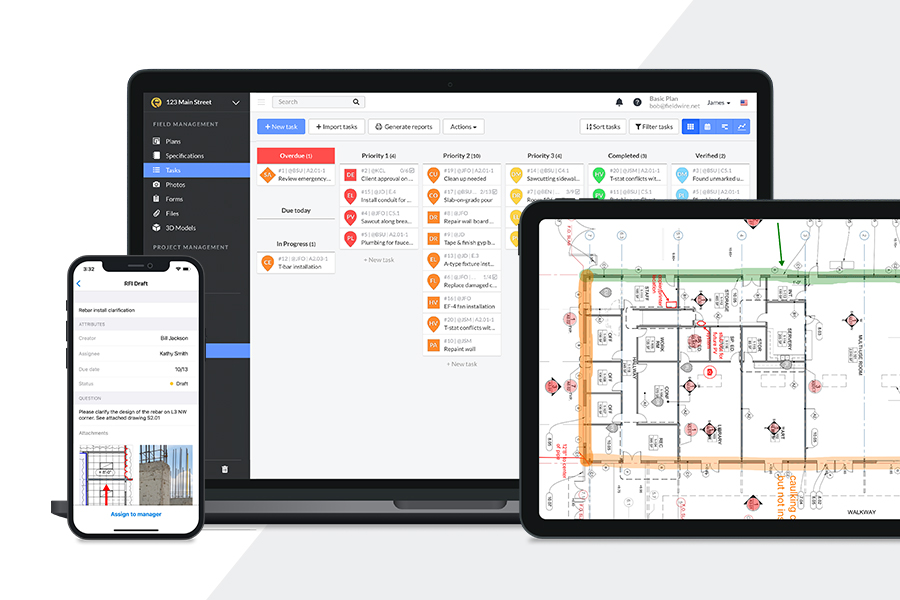

A construction management app like Fieldwire can simplify the inspection process, reducing stress or unnecessary steps for your teams.

With Fieldwire, you can quickly survey and record content through tasks to report your findings to the appropriate team members, helping ensure that every aspect of the project is built to plan.

Be consistent

By conducting inspections with the same criteria each time, contractors can ensure nothing is forgotten and that the inspection is thorough. With Fieldwire, construction teams can create template checklists to drive quality and consistency when conducting inspections.

Having a comprehensive checklist not only ensures all relevant areas are examined, but also allows companies to track progress and identify trends during the inspection process.

Communicate in real time

Clear and timely communication between teams can improve the productivity of a construction project by reducing time spent looking for information and reducing risks. The same goes for inspections. By using Fieldwire’s punch lists, tasks, and checklists, contractors can ensure everyone is informed of the inspection’s progress, from field workers to office stakeholders.

If any punch items or safety hazards suddenly arise during an inspection, you can create a task for it in the construction management app and assign it to the appropriate person for immediate attention, making the resolution quicker and more efficient.

Document every step

Maintaining a detailed record of the inspection process provides traceability and accountability, and can make it easier for construction teams to identify and address issues.

With a construction management app like Fieldwire, all the information of a project’s inspection can be documented in real time, including start and end dates, photos, status, and location. You can add value to your inspection process by sending detailed reports to all the stakeholders on your project with Fieldwire, and even use the scheduling feature to send out reports automatically.

Improving productivity with inspections

Being diligent when handling construction inspections is the key to achieving great results, like top notch quality and improved productivity. Adopting best practices when conducting inspections is the best way to reduce rework, avoid delays, and stay within budget.

Taís Oliveira •

Taís Oliveira •