Five Construction Productivity Challenges

Why is productivity a problem in construction?

The construction industry’s annual productivity growth has only increased by one percent in the past 20 years. This number is even more impressive when compared with growth of 2.8 percent for the total world economy and 3.6 percent in the case of manufacturing.

This lag in productivity can impact the profitability of construction projects and make it difficult for companies to remain competitive. Improving efficiency is therefore crucial for the success of the industry as a whole.

How is productivity measured in the construction industry?

Productivity in the construction industry is often assessed based on the amount of work that is accomplished in a given period of time. This can be calculated as output per labor hour, with output typically measured in physical units such as square footage, or financial units such as dollars.

What factors influence productivity in the construction industry?

The factors that influence productivity can be grouped in three categories:

- Labor characteristics – Age, skill, experience, leadership, and motivation of the workforce.

- Work conditions – Job size and complexity, site accessibility, equipment use, and other project-specific factors.

- Non-productive activities – indirect labor, rework, work stoppages, and other activities not directly resulting in productivity.

For an in depth explanation on how to measure productivity in the construction industry, read our blog article “Construction Labor Productivity: How to Measure and Improve It”.

The main issues with productivity and efficiency in construction

The construction industry’s productivity lag can be attributed to five trade-specific problems: lack of technological advancement, miscommunication, coordination issues, inefficient use of time, and lack of context around tasks.

1. Little to no use of construction digital tools

Given the complexity of construction projects, it can be challenging to keep track of all the changes that occur on a daily basis – think of how daily reports, punch lists, and blueprints are constantly updated. Traditional tools like paper and pen are prone to errors and can make it difficult to disseminate information efficiently, leading to delays and miscommunications that can impact project timelines and budgets.

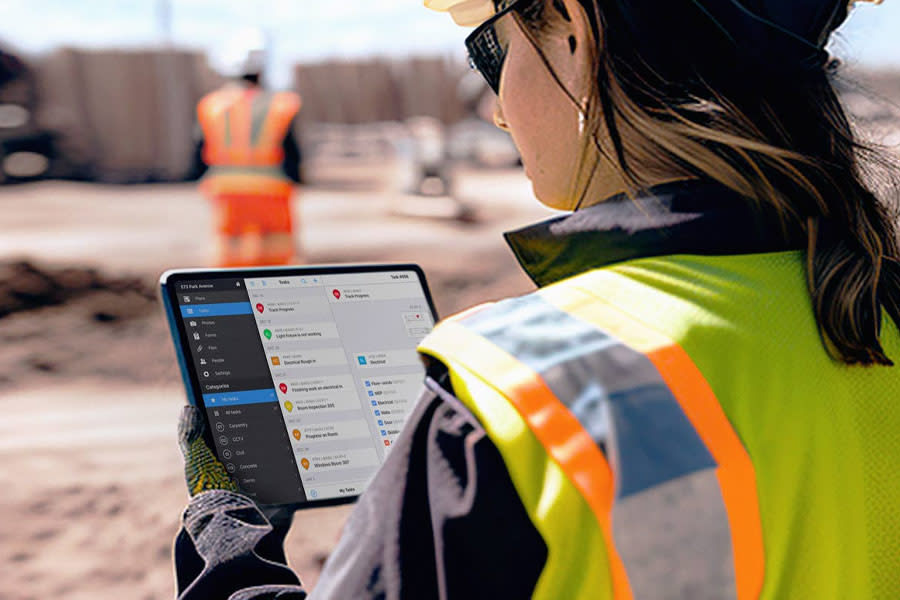

There are hundreds - even thousands - of hands on deck for construction projects, and teams need to adopt construction digital tools that will make the process smoother. Starting the digital transformation of construction companies can be as simple as adopting an all-in-one software like Fieldwire, that is easy to use on the jobsite and at the office.

Sign up for a free demo to understand how Fieldwire can help you increase productivity and efficiency on the jobsite.

2. Lack of good communication on the jobsite

Miscommunication and inaccurate data onsite contribute to $31 billion wasted on rework. That is why verbal communication can no longer be the only way to relay information on projects. Having documents updated on real time and a centralized platform to ask questions and give information can improve communication on the jobsite – and therefore the teams’ productivity.

Related: See our tips for multigenerational communication on the jobsite

3. Coordination issues

Each construction project can have hundreds - or thousands - of workers, each assembled in different roles with varying goals, creating potential miscommunication. Lack of coordination among all these teams leads to mistakes and therefore a waste of time and money.

You can resolve these coordination issues by using a task management software that can be easily used by all teams, from contractors to foremen, is key to achieving operational efficiency in construction.

4. Inefficient use of time

Thirty percent - that is how much time a craftsperson spends on actually building. The other 70% is allocated toward preparing for tasks, gathering equipment and materials, and sometimes even waiting to be instructed on what to do next. This inefficient use of time results in projects exceeding their deadline and significant cost overruns.

To solve this problem, reducing time spent on managing tasks and looking for updated plans and documents is essential to increase efficiency, save time and money on building projects.

5. Lack of context when managing tasks

Craftspeople are often given tasks with insufficient context. Simply put, they are told what to do, but they aren’t given the information needed to complete a task efficiently. This issue contributes to the construction industry’s already staggering operational waste. Right now, the sector is wasting $1.6 trillion due to its lag in productivity.

Using a task management tool like Fieldwire allows construction companies to add plans, photos, or forms that would help construction teams fully understand what they need to be doing and where they should be doing it. This reduces operational waste and results in more efficient project completions.

How can you increase productivity at the job site?

A lot of factors are involved when it comes to increasing efficiency in the construction industry, but there are three things you can do now to improve productivity on the job site:

- Digitalization: Incorporating technology, such as project management software like Fieldwire, can help streamline processes and increase efficiency.

- Clear Communication: A centralized tool for communication is essential to minimize misunderstandings, avoid rework, and ensure that everyone is on the same page.

- Effective Planning: Planning and managing tasks efficiently is crucial to ensure that the project is completed on time and within budget.

Tara Callinan •

Tara Callinan •