Best Practices for Prefab Construction

What is prefab construction? Look around your house or office. How many items came from a box? Maybe your desk, a couple of chairs, or that rickety stool no one can sit on.

Now, look where you’re standing. Have you ever wondered about the building you’re in, and whether it, too, came out of a box?

Also known as offsite construction, prefabricated (or prefab) construction is the practice of assembling parts of a structure in a manufacturing site, and transporting them to a different location. One prefab construction method is the idea of assembling building structures like furniture, also known as kit-of-parts construction. By using this prefab construction technique, building elements no longer need special on-site processing or handling; reducing the installation time, materials wasted, and risks of accidents. In the ever-evolving world of sustainable construction, prefabrication is helping to save time, waste, and the environment.

The IKEA-ization of buildings and parts is generating hype in the industry; with more and more owners adopting prefabricated construction methods. From McDonald's shopfronts to residential bathrooms, prefab structures are popping up everywhere — including in Arizona, where six chicken aviaries were assembled by Texan construction company, Ag Installers. How did they do it? Here are four ways Ag Installers use Fieldwire’s construction management software for successful prefab projects:

1. Simple inventory management

Ag installers, based in Texas, is a construction company specializing in the installment of cage-free aviary systems. In 2015, they were contracted to do the aviary install work on the Lone Cactus Egg Farm in Bouse, Arizona. The owner, Rose Acre Farms (the second largest egg producer in the U.S.) wanted six barns built onsite to house a total of 2.4 million hens. The aviary system, however, which sits inside of the barn, was constructed in Italy and sent to Bouse in containers.

A total of 12 million partially prefabricated construction materials arrived onsite for Ag Installers to assemble; a process that could take double the amount of time if it weren't partly-constructed offsite. In fact, prefab buildings go up 30% - 50% faster than traditional construction buildings, taking a project from conception to completion quickly and easily — reaching that coveted return on investment fast. With high-quality inventory management, prefab construction is almost as simple as building a bed frame — just with a few more parts.

2. Streamlined communication with the manufacturer

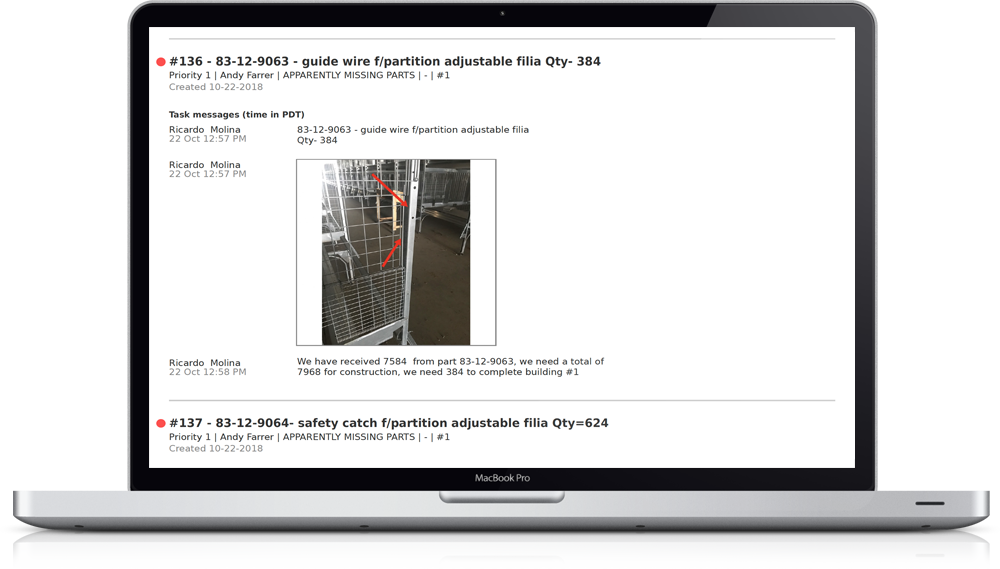

In prefab construction, inventory is everything. When dealing with such a high volume of inventory, it’s important to have a system in place that helps you manage everything — from scheduling to reporting — seamlessly. Hence why Ag Installers implemented Fieldwire — to help them track millions of parts and communicate with the manufacturer in China. Using Fieldwire, the Ag Installers team communicated in real-time and annotated all details about missing parts in one place. With so much inventory to keep track of across the site, a new employee was hired to solely track missing parts using Fieldwire’s construction task management app.

President of Ag Installers, Enrique Mendez, said having a platform which enables clear and transparent communication is critical for the success of prefab construction projects. He said: “When we can’t find a part we’re looking for, it gets logged as a Fieldwire task and added to the ‘missing parts’ category. The part number, a description, pictures, location, and the quantity we’re missing is also added. We assign the task to the manufacturer and leave it as ‘open’ until an order is placed. Then we ‘verify’ the task to communicate it has been resolved,” said Mendez.

This, combined with the productivity gains associated with prefab construction methods, helps Ag Installers stay on schedule and budget. Waste is reduced because various parts of the aviary are manufactured to fit according to plan, and productivity increases with Fieldwire onsite. In fact, having the ability to track and report missing parts from any device in the field saves Ag Installers eight hours every week on their prefab projects.

3. Efficient and accurate site reporting

Fieldwire is used to communicate hundreds of missing parts in a detailed report to the general contractor and manufacturer. According to Greg Schonefeld, the CEO of Ag Installers, these weekly reports are 15-20 pages long but easily generated using Fieldwire. He says being able to forward a report rather than bombard a manufacturer with emails and spreadsheets every day is strengthening the relationship between all parties involved and saving everyone time and money onsite.

4. Detailed documentation to avoid disputes

Working with individuals on prefab construction projects who are located in a different part of the world can become quite challenging without the right tools in place. If site issues or observations are not documented clearly, resolving disputes can become quite complicated, and in the words of Schonefeld, “a case of he said she said.”

Having all missing parts documented and accounted for in Fieldwire saved Ag Installers $82,000 on a single issue on one prefab project! Schonefeld said: “One of our customers sent us a bill and said we owed them $90,000 in damages and lost parts. We spent about two hours searching for information in Fieldwire and realized they had charged us $82,000 more than what we actually owed them.” Without Fieldwire as their source of truth, Ag Installers could have lost that money and damaged their reputation in the industry. As they put it themselves:

Check out our customer story on Ag Installers to learn more about the value in using construction management software for prefabricated construction projects. Or request a demo of Fieldwire today!

Tara Callinan •

Tara Callinan •