What are the key construction industry trends to watch in 2025?

The construction industry is evolving fast, with technology, sustainability and project management advancements reshaping how things get done. As a subcontractor, staying on top of these trends is essential for keeping your edge.

Whether adopting new tools like drones and 3D printing or navigating shifting environmental regulations, staying informed helps you work smarter, deliver higher-quality results and meet your clients' growing demands. Staying up to date positions you as a leader and ensures you’re ready for whatever challenges come next.

1. Integration of advanced construction technologies

Robotics, drones and 3D printing transform jobsites and create ample opportunities for you to work efficiently. Drones can streamline site surveys and monitor progress, while robotics automate repetitive tasks like bricklaying, freeing time for complex work.

But the real game-changer is 3D printing. Embracing this technology can lower residential building costs by up to 45% by cutting down material waste, labor expenses and build time while giving you more flexibility and sustainable options. It’s an exciting way to stay ahead, boost productivity and deliver what clients want.

2. Modular and prefabricated construction

Modular and prefabricated building approaches offer great benefits. These methods involve assembling building components off-site and bringing them together on-site, which can significantly accelerate timelines and boost consistency.

For you, that means fewer delays and a more predictable workflow. The quality is often higher since the parts are made in controlled environments. To take advantage of this shift, you can partner with prefabrication companies or integrate it into your processes. Adapting to these trends allows you to take on more projects, work efficiently and deliver reliable results.

3. Increased adoption of sustainable construction practices and equipment

Green building methods innovate construction processes, and embracing them can set you apart. Using energy-efficient systems like solar panels and eco-friendly materials like recycled steel or bamboo can help reduce your projects' environmental impact. Start offering green solutions to clients and consider getting certified to position yourself as a sustainability expert. LEED and other eco-friendly qualifications can give you a competitive edge and show your commitment. They will help you attract business in the growing market for sustainable construction.

Using construction equipment with a sustainable mindset is also a big trend for 2024 and beyond. Whether switching to electric machinery, keeping equipment maintained so that it works optimally, or leveraging equipment from remanufactured parts there are various ways for you to implement this trend. In fact, remanufacturing only uses about 20% of the energy necessary for manufacturing new parts. Renting machinery over purchasing is another go-to trend with the market set to reach $181.81 billion by 2031. Renting is not only a more cost-effective way to leverage a wide range of machinery but also helps construction companies reduce their overall carbon footprint. Consider how you can optimize your machinery, rent equipment or utilize electric equipment.

4. Data-driven project management

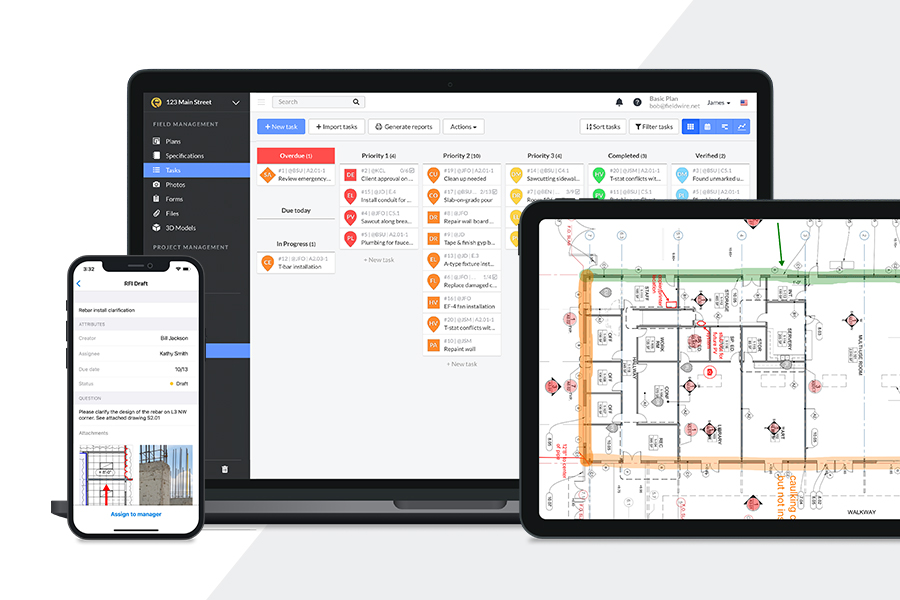

Construction management software and real-time data tracking can improve how you handle projects, offering more transparency and control than ever before. With these tools, you can prevent cost overruns, boost profitability and make better, data-driven decisions. Live updates also allow you to monitor progress, manage materials and keep an eye on budgets.

These tools also improve project efficiency and communication for subcontractors. Their features make it easier to collaborate with teams and fix issues before they snowball. Embracing these technologies puts you in a better position to deliver top-notch work while staying within budget and schedule.

5. Emphasis on health and safety regulations

In 2024 and 2025, new regulations focused on improving jobsite safety will continue to roll out and place more emphasis on preventing accidents and ensuring worker protection. As a subcontractor, you must stay compliant with these evolving safety standards and take proactive steps to mitigate risks on-site.

This involves following the latest safety guidelines and adopting innovative technologies that can help keep your team safe. Tools like wearables — helmets with sensors, smart vests and real-time monitoring devices — allow you to track worker health and site conditions. Embracing these technologies will enable you to meet regulatory requirements and create a safer, more efficient work environment.

6. Labor shortages and workforce development

The ongoing labor shortage is hitting project timelines hard, with the sector needing over 500,000 additional workers to meet demand. This makes workforce development and specialized training more important than ever. Upskilling your team can boost productivity and fill critical gaps.

Automation is another way to tackle this challenge because it helps you streamline repetitive tasks. Partnering with educational institutions is also a practical strategy, as it gives you access to freshly trained workers that help you stay ahead in a competitive labor market. With these approaches, you can keep your projects on track despite the labor crunch.

7. Supply chain challenges and material costs

Ongoing supply chain disruptions drive up prices and make it challenging to get materials. In fact, wood, plastics and thermal protection materials can increase in price by as much as 6.5% annually until 2025. Managing these rising costs is critical. Bulk purchasing when prices are lower or locking in long-term deals can help you control expenses.

It’s also wise to explore alternative suppliers to stay flexible when shortages hit. Building solid relationships with your suppliers is imperative, too — it can give you priority access to materials and help you avoid delays. Staying ahead of these challenges can keep your projects running smoothly and on budget.

Staying ahead in a competitive industry

Staying informed and adapting to emerging trends is essential to staying competitive in the ever-evolving construction industry. Embracing new technologies, sustainability practices and continuous upskilling can position you as a leader, allow you to take on more opportunities and deliver top-quality work that keeps you ahead of the curve.

Rose Morrison •

Rose Morrison •