The great cost of inefficiency: What is poor project management truly costing your construction company?

Project managers are pillars of operational efficiency for construction professionals and subcontractors. They are the minds behind implementing innovations like artificial intelligence (AI) or software solutions, finding improvement opportunities on and off the jobsite. Negligence of construction’s primary oversights costs organizations more than money — it sacrifices safety, innovation potential and productivity.

Deficient stakeholder communication

Subcontractors may need to hear more from stakeholders with the most project influence. As the voices between clients, suppliers, and workers, they are responsible for communicating priorities, budgets, and timing changes. Construction profit margins are already slim, so project managers must incorporate changes with finesse.

When project managers and stakeholders fail to do this, subcontractors suffer. A 2022 survey revealed labor inefficiencies were the reason behind between $30-$40 billion in losses. Incorporating software and next-generation communications may overcome misalignments leading to probable reworks or inflated budgets.

However, careful tech installation is necessary. Otherwise, construction companies may develop unintended silos that separate subcontractors.

Inadequate project planning and scheduling

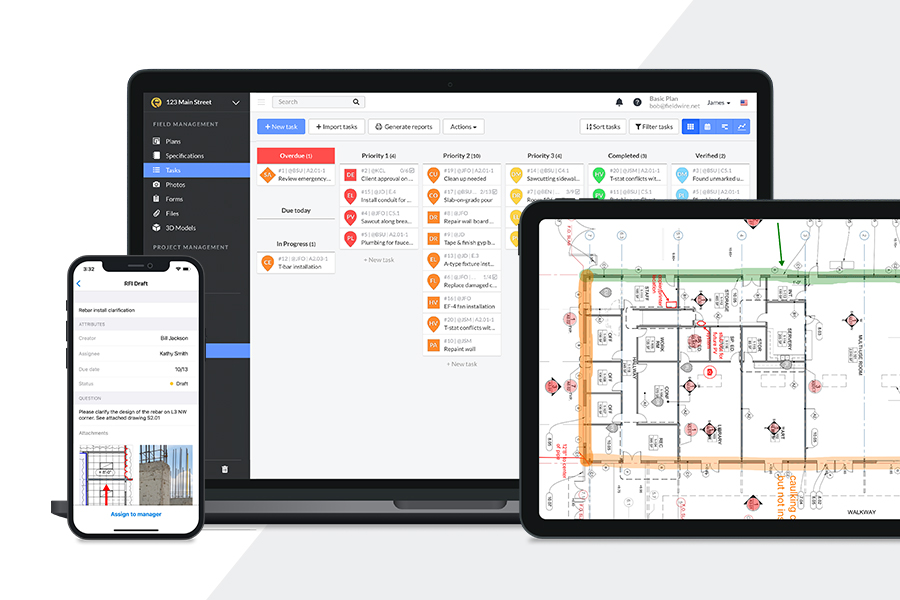

If project managers fail to consider disruptions or to see a build’s finish line, the foundation could crumble. Software with assets like AI and machine learning could use predictive analytics to surmise project estimates with mobility.

This helps subcontractors because it delivers realistic estimates without adding too much pressure. Software also has the potential to increase communication with instantaneous project updates, but mismanaged use could hinder real-time notifications.

Construction managers have numerous moving parts, including procurement and shipping professionals. If there are bottlenecks and delays, it impacts subcontractors’ performances. A lack of coordination could encourage expedited workflows or downtime depending on the circumstance, causing increased safety incidents or overhead.

Low mitigation of risk

Software may keep logs on incident reports, and subcontractors usually have the most injuries. Project managers who use this data have a better shot at risk mitigation than those that do not. Inadequate personal protective equipment or safety training yields unforeseen expenditures from workers’ compensation claims or, at worst, litigation. This becomes more complicated with subcontractors, depending on the contract details.

Crisis management also assists productivity. Using prevention through design alongside construction software increases the chances that every phase of a subcontractor’s journey will have proactive safety plans. The Port of Portland incorporated this practice and won an award for leadership and worker safety because of it, making this $325 million project and its contributors stand out in the industry.

Poor resource allocation

Sustainability is at the top of construction project managers' minds, especially regarding eco-conscious resource management. Around 83% of building companies want to promote green construction, and low emissions and waste is only certifiable with the help of software and data. Project managers risk misplacing materials, equipment and laborers without an efficient planning structure.

Misallocated resources could be one of the most lengthy stopgaps between a project and its completion. Understocking and overutilization leave subcontractors with no direction in the short term, and enterprises need to pay overtime if they refuse to shift project deadlines because of the delay. This leads to tired workers, causing more inefficiencies and costs as errors appear and morale dips.

Inconsistent quality assurance protocols

Managers have the final say in whether a project meets their standards or not. If they are the hands-off type, then subcontractors cannot learn the firm’s expectations or have additional checks and balances on the jobsite’s quality. Inefficient review protocols and nonexistent quality assurance are more straightforward to dictate with next-generation technologies.

Subcontractors could use software to find detailed checklists to do final evaluations. They can review past projects with similar specs to see how their work varies and submit photos for an AI to review for potential oversights. The possibilities are endless when it comes to saving time and money from defects.

Reluctance to adopt innovation

Construction is one of the most resistant sectors to change for several reasons, including its older staff base and high initial investments. One in five construction professionals is over the age of 55, making it challenging to enact widespread change. However, early adopters often witness efficiency improvements and cost savings, in addition to the competitive advantage and increased trust with subcontractors.

Incorporating technology, like automation and software, boosts productivity because it performs tedious tasks faster than manual efforts and with greater accuracy. Project managers also develop better visibility over their sprawling staff bases by gathering information on their performance with innovative technologies.

Neglecting workforce training

The digital applications for training contractors are infinite, from augmented reality to remote conferencing seminars. Construction companies often handle workers from numerous places, so creating consistency among them is critical for delivering the same quality to clients, especially returning business-to-business customers.

Project managers without tech assets may have no space for subcontractors to submit feedback or communicate with workers from other job sites. Work style variances breed inefficiencies and tension between collaborators. Dissatisfaction could lead to high turnover rates and increase recruiting costs for construction organizations.

The true cost

Construction firms cannot afford the productivity, financial and time costs of ignoring technology. Automation is too powerful and subcontractors are desperate to upskill their digital prowess. Poor management creates resistance among workers, who have little loyalty to specific contractors. Instead, they will flock to opportunities placing them in safer work environments, embracing the future and breaking construction’s expectations.

Rose Morrison •

Rose Morrison •