Technology integration enhances construction project efficiency and sustainability

Working in the construction industry requires you to focus on deadlines. Utilizing technology in this space is essential for productivity, but you must know which tools and solutions are worth your time and money.

Technology is ever-changing, but there are several tools you can use to get the most out of your crew — all while keeping your efforts sustainable.

Here’s some technology your team might consider for efficiency and sustainability in the construction field and how you can use innovative software and devices.

Impactful developments in the construction industry

Not long ago, engineers primarily relied on manual measurements and personal experiences to create plans. Now, technology is at the core of the planning, building and inspection stages.

No two construction jobs are identical — this leaves a demand for resources that let you view data, keep workers safe and anticipate challenges. Here are some of the most impactful developments in the construction industry to date:

-

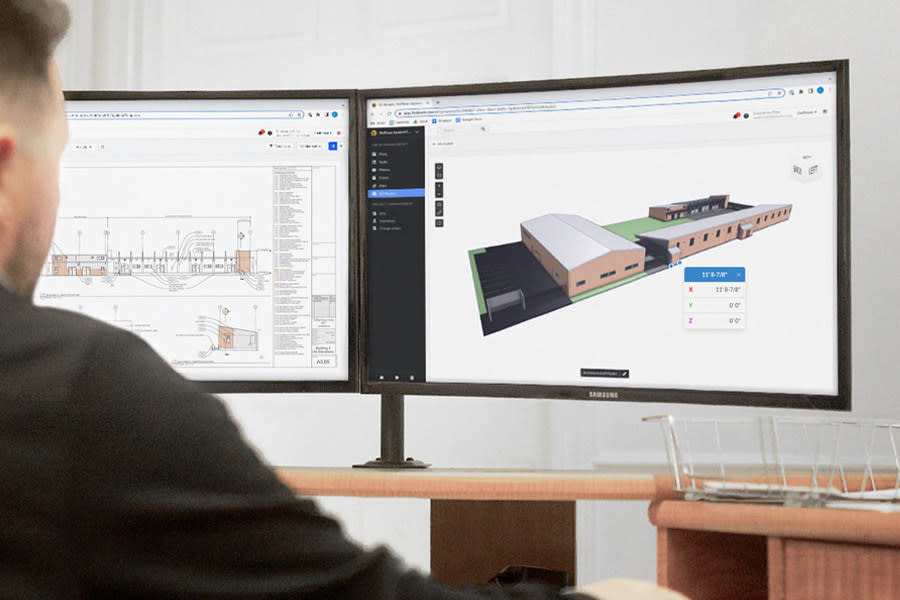

Building information modeling (BIM) software: BIM technology lets professionals create three-dimensional models of buildings and physical structures. Integrate BIM software into your workflow to streamline the design phase.

-

Laser scanning equipment: Your construction business may rely on laser scanning technology to document landscape conditions. Laser scanning effectively shows experts the locations of slopes, water sources, trees and utility lines before a job.

-

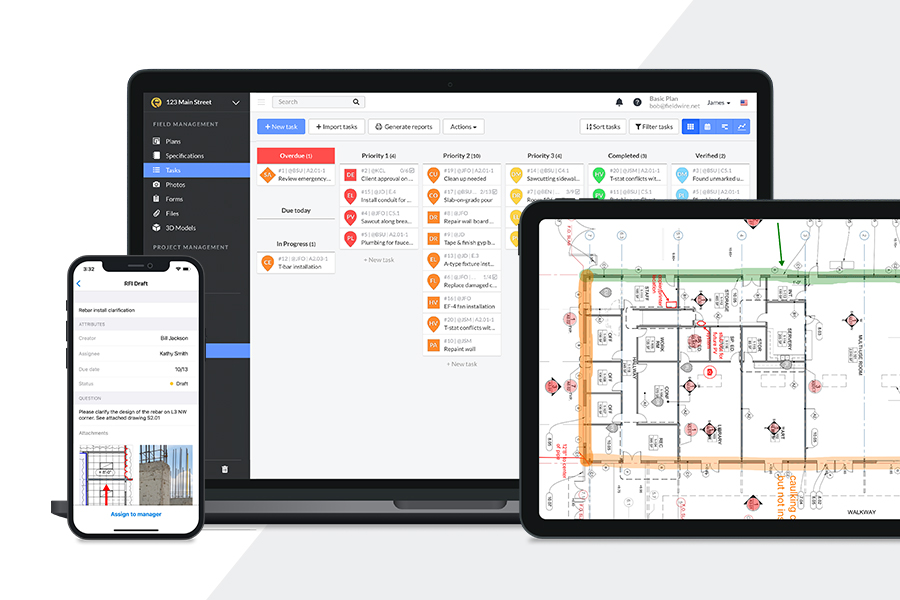

Construction management software: Manage several aspects of an assignment from one mobile application. Companies use construction management tools to allocate materials, message stakeholders and monitor spending.

-

Wearable protection equipment: You might adopt safety glasses and helmets with cameras to provide real-time footage for project managers. Making informed decisions on the spot becomes stress-free without traveling back and forth to sites.

-

Virtual reality and simulation: VR technology makes it possible to train workers to operate machines without using company resources. Before putting individuals on a site, place them in real-life situations to see how they respond.

1. Using BIM software for a careful approach

Efficiency and sustainability in the construction industry mean completing work once. Using BIM software makes it easier to leave zero room for error. You can also clearly define project objectives for teams working in different locations.

Your construction company may be responsible for creating a city’s new road system. Generating a digital model with BIM software shows builders what the finished product should look like.

Only running concrete pavers, excavators and wheel loaders when necessary decreases carbon emissions and prevents material waste, resulting in a more sustainable approach.

2. Incorporating laser scanning equipment for precision

Laser scanning equipment is useful in identifying landscape obstacles before reporting to a site.

Many construction projects call for driving heavy machines for digging, trenching and demolishing structures. When experts use laser scanning equipment, workers better optimize the use of materials, understand property lines and mitigate adverse effects on the environment.

Three-dimensional scanning enables experts to verify ideas for working with what is already on a piece of property. Removing only the trees needed to progress with an assignment to abide by regulations involving protected property lets workers dodge hurdles.

3. Minimizing environmental impacts with construction management software

Building projects are mapped out months or years in advance. The right construction management software tools give you the power to make educated decisions about the quantity of materials you’ll need and the date you’ll require them.

Construction management software is a productivity hack for businesses. Most tools allow you to track and change your orders from one platform.

Ordering supplies after using BIM software helps you provide accurate numbers to manufacturers. This keeps building material returns to a minimum, which results in fewer carbon emissions from trucks that haul supplies from point A to point B.

4. Viewing camera footage to make informed decisions

Construction teams work in tight spaces. There may be scenarios where collecting real-time video footage is needed for underground work — like installing new pipelines, finishing electrical repairs or maintaining drainage systems.

Improving the communication process between decision-makers in an office and employees on a job site can shave hours, days or weeks off a project’s timeline.

Keeping construction managers from driving between different locations saves your business miles on company vehicles and stops you from burning fuel that could be used elsewhere. Also, your team does not need to alter surfaces multiple times when making a judgment call for a job.

5. Creating opportunities for training with virtual reality

Construction jobs are all about using equipment correctly to ensure employee safety and efficiency. Implementing a virtual reality training program is a useful way to educate your staff on the procedures you expect them to follow and verify that resources are used properly.

VR and simulation-based training in the construction industry allows you to review employee comprehension and abilities with machines in controlled environments.

Reduce the risk of completing rework, running machines longer than your business anticipates and contributing to CO2 emissions within your industry.

Ensuring your team is updated on the latest training effectively reduces the chances of repairs and downtime because of accidents. Enroll employees in a virtual reality training session that sets the standard for performance and phases out unnecessary wear and tear on your fleet.

The value of efficiency and sustainability in construction

Here are reasons to prioritize efficiency and sustainability practices when working in the construction world:

-

Reduce construction waste: Salvaging what you can of preexisting structures can create a cleaner environment with less waste ending up in landfills.

-

Optimize cost savings: Using equipment efficiently keeps your fleet from working overtime, reducing the need for serious repairs.

-

Streamline material selection: BIM and construction management software simplify the material ordering process. Your building plan may qualify for Leadership in Energy and Environmental Design (LEED) certification should your project follow green building standards set by the U.S. Green Building Council (USGBC).

-

Shrink your carbon footprint: Reducing your carbon footprint throughout the construction process and making environmentally friendly material choices is essential since 39% of greenhouse gas emissions come from buildings worldwide.

Prioritize efficiency and sustainability with these construction resources and practices

Every step of the construction process must be well-calculated for positive results. Fine-tuning how your team works and staying updated on the latest technology and tools allows you to operate effectively and limit your environmental impact.

Consider these five technologies to put your best foot forward during every project you complete. Working efficiently and sustainably can improve your brand reputation and help you take on new opportunities in the field.

Evelyn Long •

Evelyn Long •