5 construction productivity thieves and 10 ways to combat them

Productivity loss translates into financial loss. In construction, where the profit margins are slim, yielding less output than projected is even more fiscally damaging. Learn about the culprits sapping your specialty contracting business’ productiveness and ways to address them.

5 productivity thieves in construction

Trade contractors deal with fewer project variables because of limited job scope. Still, you may underdeliver and ruin your reputation due to these factors.

1. Unidentified errors

Although all construction professionals make mistakes, only the careless forgo implementing strategies to combat them. Self-inflicted mishaps hurt because you are often to blame. Unfortunately, these mishaps reflect adversely on your brand, causing general contractors and other subcontractors to question your professionalism.

For example, inadvertently accepting too many jobs almost always results in scheduling issues. Contingencies force you to spend more time per project than initially thought, causing holdups. Misjudging your capacity to finish on schedule means failing to exercise due diligence — it doesn’t bode well for your trustworthiness moving forward.

2. Lengthy lead times

Recently, overseas construction deliveries have taken longer than expected to arrive. Concrete, masonry, stonework and roofing contractors are the most vulnerable since the supplies they need generally come from foreign sources.

While most supply-chain issues are beyond your control, you still need to ensure you choose wisely who you source building materials from. With little visibility, it can be challenging to identify the weak links in your supply chain and address the situation accordingly.

3. Faulty assets

Construction equipment sometimes has a mind of its own. However, heavy machines and power tools rarely quit when appropriately maintained. Regardless of the malfunction’s nature, broken gear negatively impacts your crew’s productivity.

4. Ineffective workers

Construction laborers and helpers can underperform for various reasons. The usual suspects are insufficient safety training and refreshers, miscommunication, vague KPIs, inadequate equipment, poor working conditions, declining physical health and mental unfitness.

5. Unmitigated inefficiencies

Issues manifest in idle machinery, redundant processes, unnecessary tasks and activities and underutilized talent. Each is a wasted opportunity to produce more.

Failing to reduce your blind spots allows inefficiencies to go unnoticed for an extended period. Allowing known nonessential elements within your workflow to persist indicates mismanagement.

10 tips for addressing construction productivity thieves

Do the following to break down the barriers to maximum productivity and generate more business.

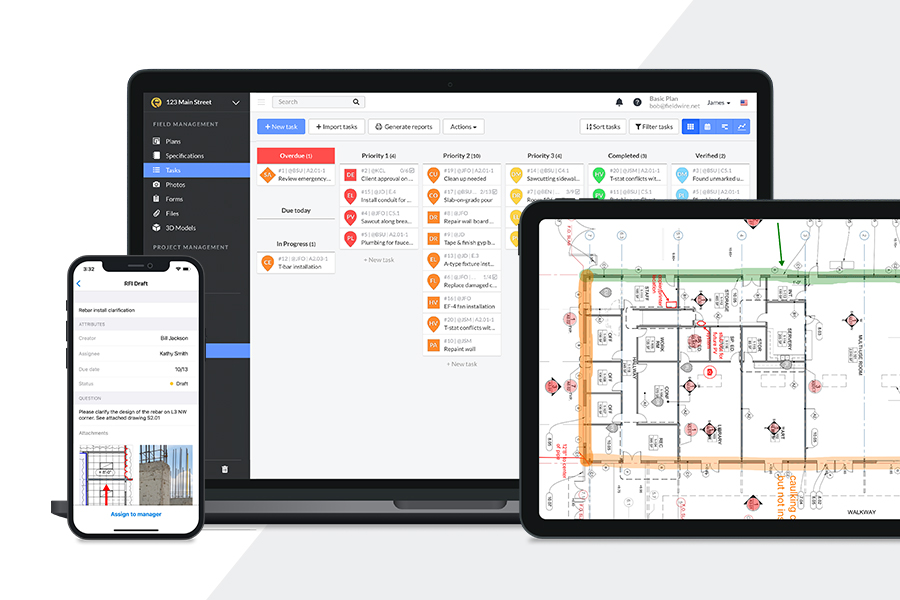

1. Digitize operations

Digital transformation is half the battle. There’s a technology solution to any subcontractor pain point.

Virtual and augmented reality can help you spot design flaws before commencing work to avoid last-minute changes and rework.

Powerful construction management software can simplify administrative work. It helps you oversee your projects closely, giving you instant access to contracts, sorting your schedules, tracking your budgets and more.

Choosing which innovation to adopt first can be confusing. Capital and training requirements are roadblocks to speedy digital transformation. Identify your most pressing productivity concern to determine which technology to prioritize. Make the transition with ample technical support to train your employees properly and prevent incompetence from affecting the solution’s effectiveness.

2. Value predictive analytics

Digital technology collects mountains of information that can reveal bad habits and past mistakes that have gone under the radar for a long time. Gleaning insights from historical data empowers you to fine-tune your practices.

Hiring a competent data scientist to crunch the numbers goes without saying. However, this professional can command a six-figure annual salary and increase your payroll significantly. If you don’t have the budget, consider using a freelancer you can hire on an ad hoc basis to cut costs and get the job done. Alternatively, leverage technology that offers you a dashboard of analytics and cut costs further.

3. Embrace circularity

Maximizing the value of anything is the circular mindset’s essence. This philosophy can help you accomplish more in less time because it compels you to maintain your machinery and tools thoroughly.

If you lack one or two essential assets for a project, consider using an equipment lessor instead of buying one. Save time on the jobsite without worrying about the hassle of tool maintenance when you utilize a tool crib management solution. You can even request demos and training for little to no extra charge to equip your operators with proper knowledge and finish tasks efficiently.

4. Streamline procurement

Source your supplies locally to shield yourself from various supply-chain disruptions. Domestic manufacturers and dealers are less susceptible to weather-related and geopolitical interruptions. Land-based cargo encounters fewer logistical difficulties in reaching intended destinations than maritime freight, shortening lead times.

Moreover, collaborating with domestic supply chain partners to boost freight visibility is easier than with their international counterparts — more cargo traceability and transparency equal fewer blind spots.

5. Close the knowledge gap

Your workers can’t do their duties well when there’s a disconnect between what you want them to do and what they think they should do. Perpetuating such a discrepancy is unproductive.

Management must disclose relevant information to the rank and file. Evaluate your crew’s performance and provide feedback regularly. Otherwise, you can’t meet your client’s project milestones.

6. Invest in youth outreach

Earthwork, plumbing, electrical, carpentry, structure framing, siding, HVAC and many other specialized construction activities are a long game and your business continuity depends on investing in the builders of tomorrow.

Seasoned carpenters may know how to connect pieces with biscuit or tongue-and-groove joints or measure ¼- and ⅝-inch radius corners for hinges with dimes and nickels like pros and can be a wealth of knowledge for the emerging workforce. However, years of hard labor can cause pain, discomfort and inefficiency for seasoned workers, resulting in drilling or sawing wood with diminished grip strength.

These realities can drag construction productivity levels down. Unfortunately, fewer replacements enter the sector than those who retire.

Although the remedy for the labor shortage can’t be addressed overnight, automation helps alleviate some responsibilities for human workers.

The status quo may be inconvenient, but you can change it by enticing young adults to pursue construction trades. In addition to partnering with educational institutions to teach students critical skills, consider offering scholarships, paid apprenticeships and mentorship programs.

Minimizing barriers to entry is one key to reversing the labor shortage and recruiting skilled construction workers in the medium and long term.

7. Put a premium on safety

Smart personal protective equipment, exosuits and wearable beacons can neutralize occupational hazards, prevent worker injury and minimize performance errors. Fewer safety incidents mean more productive hours per laborer and helper.

8. Launch a thoughtful wellness program

Construction work is as psychological as it is physical. High-pressure responsibilities, taxing tasks, long hours, burnout, financial distress and a toxic culture can negatively affect your team members’ mental health.

Developing a wellness program can keep your crew in a positive headspace. Such an initiative can lessen absenteeism and medical or disability leave, ensuring your most valuable resources — your employees — are constantly productive.

Foster a safe environment and a climate of acceptance to erase any stigma of vulnerability. It can encourage your workers to open up about their struggles. Consult a wellness expert to help craft a healthy program for your team instead of letting them turn to harmful outlets like excessive substance use and forms of escapism.

9. Eliminate wasteful practices

Lean thinking can make your workflow as efficient as possible. Overproduction and unnecessary movement of workers, supplies and equipment sitewide are two common inefficiencies plaguing different breeds of subcontractors. Trim the fat until there’s no more left.

10. Aim for realistic goals

Overpromising may snag you deals but can lead to revenue loss if you fail to keep your end of the bargain. Promising the stars to your clients and setting unreasonable expectations for your workers is a productivity killer.

Unattainable goals drive down employee morale because nobody will feel good about themselves when they think they can’t measure up, no matter how hard they try.

Steal these pieces of advice to combat construction productivity thieves

Addressing the numerous causes of productivity loss in specialized construction projects may be overwhelming, but it’s possible. Technological advancements and project management tools make huge leaps forward in improving efficiency and streamlining communication. Apply these tips and find software that works for your business to notice a marked improvement in your crew’s performance and output.

Rose Morrison •

Rose Morrison •