The difference between QA and QC in UK Construction

“Quality Assurance” and “Quality Control” are often times mistakenly used as interchangeable terms when discussing the broad issue of quality in UK construction; however, these two terms actually describe very different activities. Although both work towards the delivery of a final product that meets the project’s specifications and customer’s expectations, they arrive at the outcome in two very different ways.

Quality Assurance (QA), refers to the implementation of proactive processes that aim to prevent defects. Quality Control (QC) simply refers to the process of inspecting the product to identify and correct defects. As a tool, QC can be thought of as a corrective tool, typically carried out by a specific group of individuals on a job site; the inspectors and project engineers who walk and document items that need corrective action. QA is a management tool that can incorporate everyone on the team through planned and systematic activities that aim to prevent defects before they occur.

In construction, we have QC down. We have building inspectors, third-party inspectors, testing labs, and an army of people walking the job site to identify any required corrective action, which may take the form of a dreaded punch list that is often generated in the final stages of a project as the pace becomes frenzied and we all work to finish, fix, and ultimately, hand over to operations and maintenance.

I think we are good at QC in construction. We tend to find our problems early and get them fixed so the client is happy and satisfied with the project. The real problem in construction is not that we hand over defective projects, it’s that before handoff we find so much that needs to be fixed! This is the rework problem that we see cited so often in the media and in the numerous studies out there that identify rework as a big issue in construction, and a major contributor to our industry’s productivity problem.

If there is any doubt, there are many studies out there that back this statement. Many reports, including this PDF from XL Catlin, put the total cost of construction at about five percent of total construction costs. One widely cited study by the Navigant Construction Forum states:

“Average rework on projects can cost between 7.25% and 10.89% of total construction cost (when both direct and indirect costs are included) and can cause an increase in the schedule (project delay) of approximately 9.8% of the planned project time.”

Where the goal of QC is to find any defects so they can be corrected before owner handoff, the goal of QA is to prevent these defects in the first place. Yes, we do QA in construction. We certainly do it in the supply chain at the materials level where quality assurance programs are in place to ensure that the materials and components we use in the course of building a project are free from defects. In general, though, we do not do as good a job focusing on QA as we do focusing on QC, and that’s partly because many people in the industry don’t understand the difference.

If the goal of QA is to prevent problems in the first place, then one of the major objectives of a construction quality assurance program is to eliminate the rework that is so prevalent in the industry. One of the major causes of rework in construction is workers in the field not having the information they need to do the job correctly the first time. Plan changes, updates, clarifications, and submittals that occur throughout the building phase of a project create a constant challenge in terms of ensuring that the latest information gets in the hands of the people that need it in a timely manner. The conditions that we are presented with simply overtax our currently used processes. These conditions are not going to change, so it’s time to look at changing the processes used to manage them.

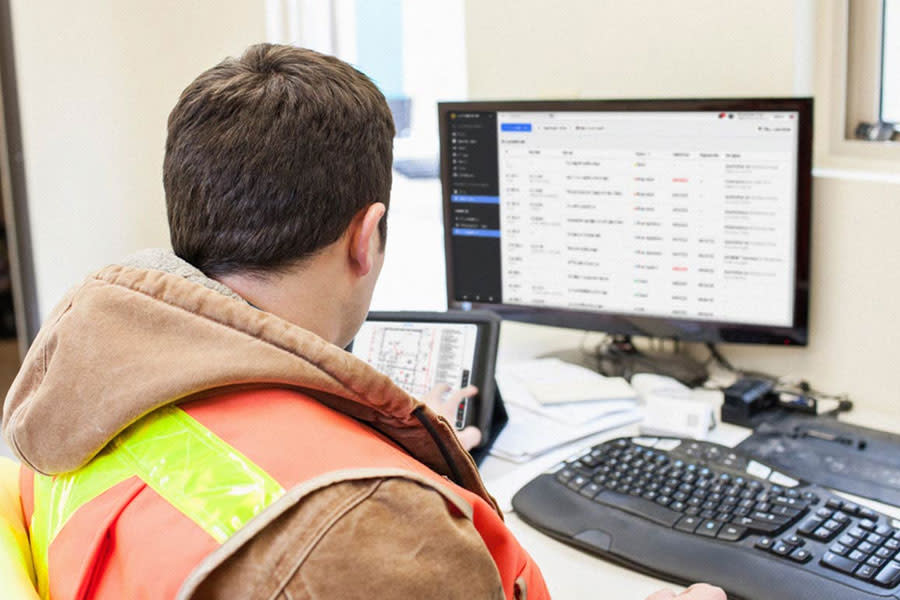

Many of the processes in the AEC industry are outdated, manual, and paper-based processes. We need to rethink many of these processes, and in many cases, we need to ditch the old ways altogether in favor of new, digital workflows that are enabled by the tools and technology that is now available.

Anytime I discuss digital workflows, I point to the RFI process. The Request for Information, or RFI, process on most construction projects is the ongoing, often a daily routine of asking a question and getting an answer about something on the construction drawings. It is an important process. So much so that we have a very formal method of asking these questions using an RFI Form that, for every question, captures who is asking, exactly when they asked, who reviewed it, and of course, the form that documents the official answer.

It’s good stuff, it’s necessary, but it doesn’t work. The time it takes from asking a question, even a basic one, to the time it takes to get an answer, is staggering. As that process unfolds, the only person that really knows about the pending question is the person that asked it. Even worse, when the question does finally get answered, the only person who really sees the answer in a timely fashion is, again, the person who asked it. Yes, the general contractor will typically send copies of the answered RFI to all the trades on the job, but this is ineffective at best. After all, if I didn’t have the same question in the first place, then what interest is it to me and my work? And who has time to sort through all those Q&A’s as they come into the office to figure out what pertains to us? None of this even begins to address how this information actually makes it into the hands of the crew in the field that are actually doing the work.

So, things get built wrong, we rely on the QC process to find those things, and then we fix them. That’s why that process and those RFI forms are so important. Because now we have to go back and figure out who is paying for the rework, and we need the data captured on those forms, so blame can be properly placed. This process needs to go away! There is no reason for it anymore, other than it has become so ingrained into the way we build that it’s tough to let go.

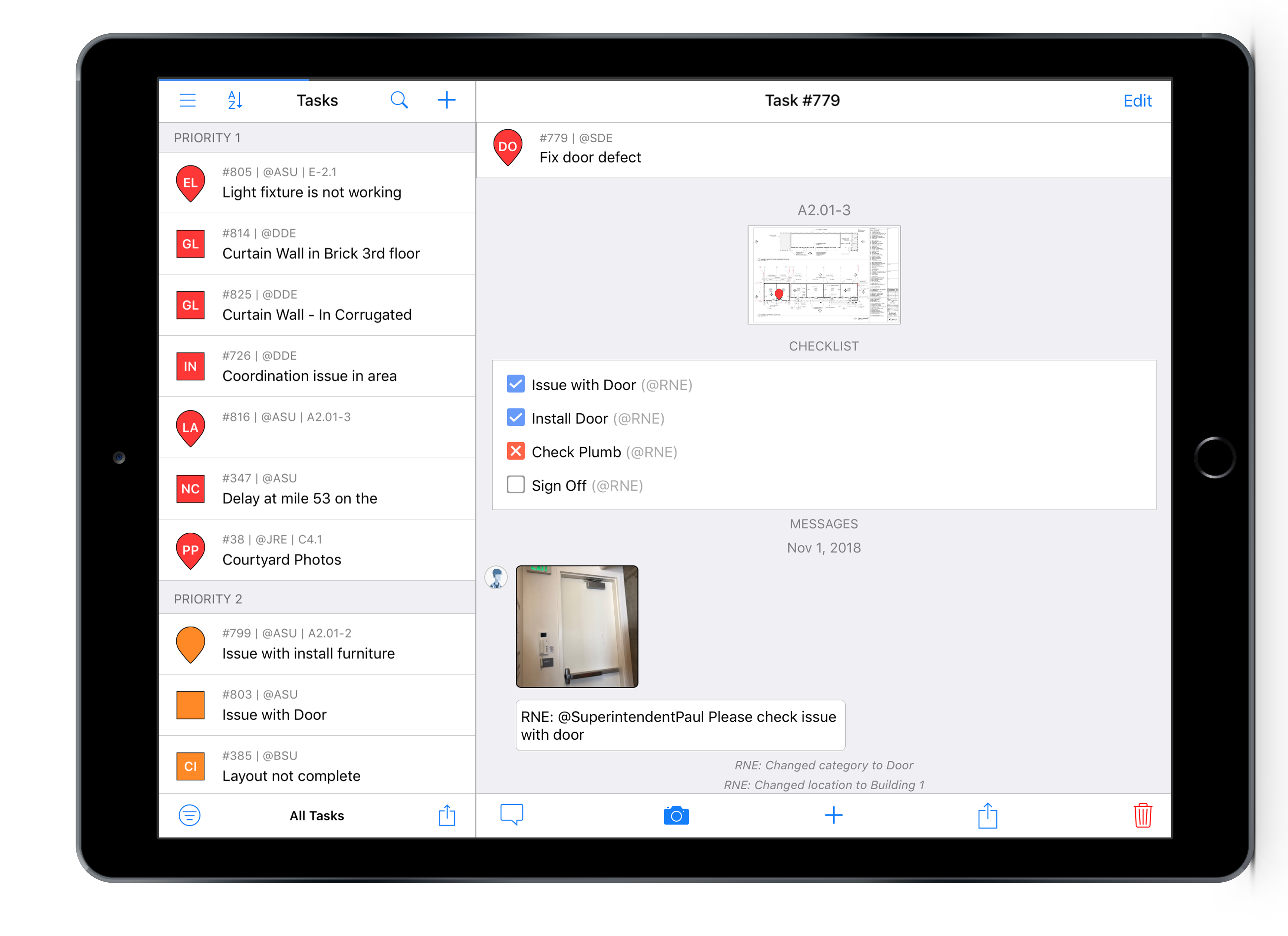

Digitizing this paper process is not much help either. Instead, we need to leverage the digital tools that we have available right now to create an entirely new digital workflow. One that is simple and effective. One that looks something like this:

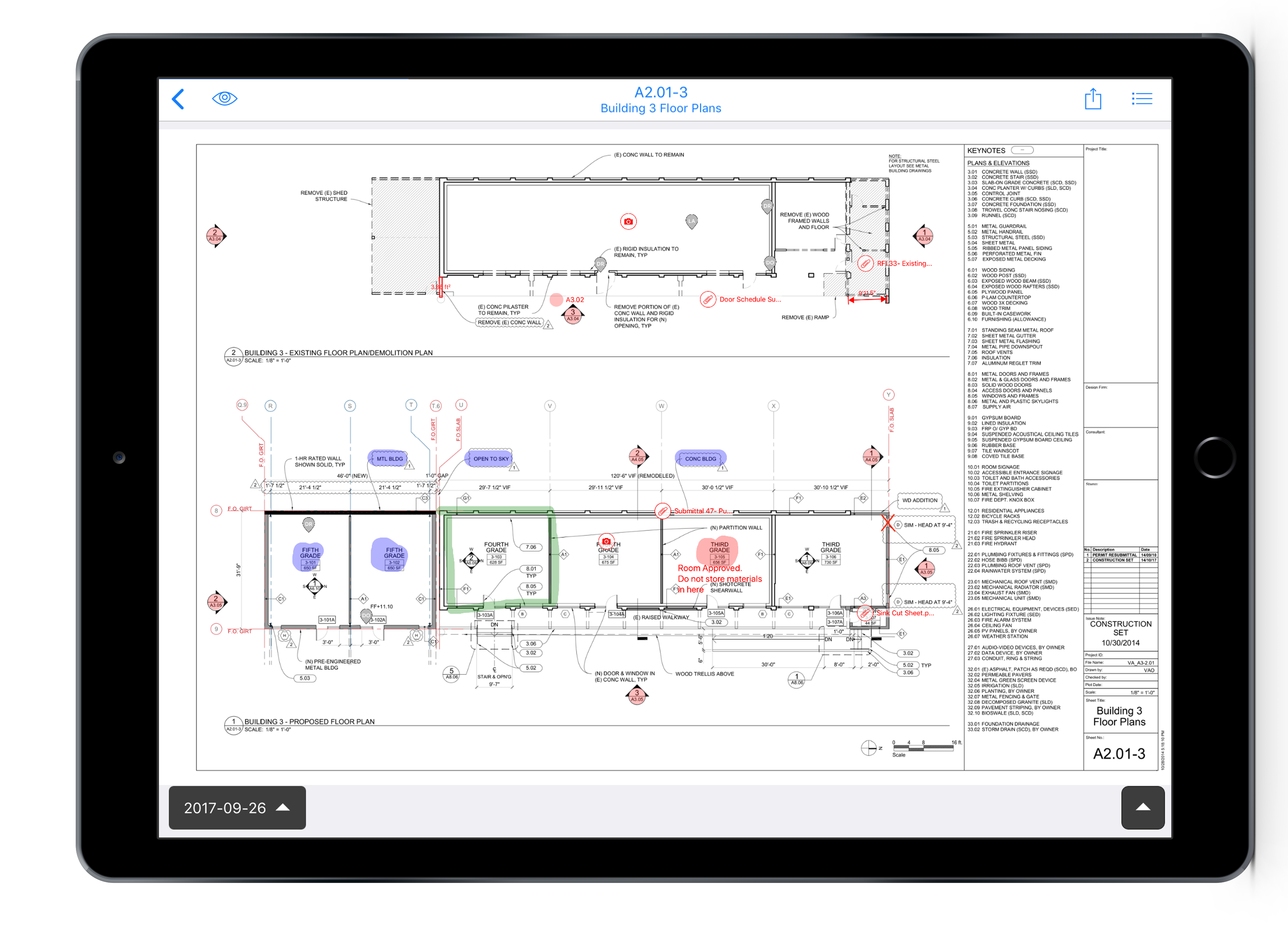

Paper drawings in the field are completely replaced by digital drawings. Questions that arise are easily asked directly on the digital drawing that is being shared and viewed by everyone. Now everyone, from the field to the office, from the construction team to the design team, can see a question has been asked. The question is assigned to the appropriate party who provides the answer. Not in a letter or an email, but directly on the digital drawing. Now everyone sees the question, and the answer, and they are forced to see it right on the construction drawing that they’re referencing in the field.

The implications and potential benefits are staggering. Delivery of information is instant and automatic. Questions and answers live directly on the drawings; the set of instructions being referenced by everyone. Field crews may see answers to questions that their office counterparts didn’t even know to ask. A tradesperson may see an answer to a question that is entirely different from the way they may have interpreted it. People stop asking the same question over and over because they can see the question has been asked. And in the field, they can see a pending question that may affect the way they are about to build before they build it wrong.

This is one simple example. There are many more. Adopting entirely new digital workflows with an eye towards quality assurance and elimination of rework is vital to our industry if we are going to improve construction’s much-discussed productivity problem.

If you want to learn more about how Fieldwire can help with the quality assurance process, you can take my course on LinkedIn Learning or just signup for a free Fieldwire account today.

Editor’s note: Fieldwire is proud to feature construction expert Jim Rogers on our blog. Jim has decades of experience in construction management and safety, and is an instructor for LinkedIn Learning — an online library of video courses taught by industry experts from across the globe. LinkedIn Learning is a great source for construction management education and content, and it’s included if you have a LinkedIn Premium account.

Jim enjoyed learning about Fieldwire so much that he created an online course on how to use Fieldwire to manage construction drawings and processes. He then created this blog post for our readers who are eager to learn more about QA/QC processes.

Jim Rogers •

Jim Rogers •